The article underscores the pivotal role of advanced industrial packaging solutions in enhancing product safety and efficiency during shipping, with a growing emphasis on sustainability. These solutions are tailored to the specific needs of products, considering factors like fragility, weight, and volume, while also safeguarding against environmental risks and transit-related damage. The industry is transitioning towards sustainable industrial packaging, utilizing eco-friendly materials and digital technologies for custom packaging designs that reduce waste and carbon footprint. Innovations such as biodegradable plant-based plastics and bio-composites are gaining traction as viable alternatives to traditional petroleum-based materials, aligning with circular economy principles. Digital printing and 3D modeling enhance design precision, while IoT devices enable real-time monitoring of goods for secure supply chains. Companies are increasingly adopting these sustainable practices, signaling a commitment to environmental stewardship and reflecting a broader shift towards green solutions in the industrial packaging sector. This evolution not only promotes responsible resource management but also positions companies as leaders in innovation and corporate social responsibility.

Industrial packaging solutions play a pivotal role in safeguarding products during transit. As global trade expands, the need for robust, yet sustainable and brand-enhancing packaging has never been greater. This article delves into the evolution of custom industrial packaging, highlighting its transformation from mere protective wrapping to a strategic tool that combines protection with brand identity. We explore key considerations for selecting eco-conscious materials, showcasing how sustainable practices can lead to cost savings and heightened product safety. Through case studies and insights into innovative design technologies, we uncover the significant impact of customization on shipping efficiency. Furthermore, we predict future trends and advancements in this domain, ensuring businesses stay ahead in the sustainability race while optimizing their logistical operations.

- Understanding the Role of Industrial Packaging Solutions in Shipping

- The Evolution of Custom Industrial Packaging for Protection and Branding

- Key Considerations for Choosing Sustainable Industrial Packaging Materials

- Case Studies: Successful Implementation of Eco-Friendly Industrial Packaging

- Innovative Technologies in Industrial Packaging Design

- The Impact of Customization on Cost Efficiency and Product Safety in Shipping

- Future Trends and Advancements in Sustainable Industrial Packaging Solutions

Understanding the Role of Industrial Packaging Solutions in Shipping

The integration of industrial packaging solutions plays a pivotal role in the shipping industry, ensuring that products are securely and efficiently transported across distances. These solutions are tailored to protect goods from various environmental factors and potential damage during transit. The choice of packaging is influenced by the nature of the product, its fragility, weight, volume, and the distance it needs to travel. Sustainable industrial packaging has gained prominence as businesses and consumers alike are increasingly conscious of their ecological footprint. The implementation of eco-friendly materials and designs in packaging not only reduces waste but also aligns with corporate social responsibility objectives. Custom industrial packaging, a subset of sustainable options, offers the added benefit of being tailored to specific product dimensions and protective requirements, thereby minimizing material use without compromising on protection. This bespoke approach can lead to cost savings and a reduced environmental impact through optimized resource utilization. As the demand for sustainability in packaging grows, innovative solutions are emerging that balance protective integrity with environmental stewardship, ensuring that goods arrive at their destinations intact while adhering to green principles.

The Evolution of Custom Industrial Packaging for Protection and Branding

In recent years, the field of industrial packaging has witnessed significant advancements, particularly in the realms of protection and branding. Custom industrial packaging solutions have evolved to address the complex needs of various industries, from electronics to pharmaceuticals. These tailored packaging options are designed not only to safeguard products during transit but also to serve as mobile billboards for brands. The integration of advanced materials, such as shock-absorbent foams and moisture-resistant coatings, has greatly enhanced the protective capabilities of these packages. This evolution ensures that sensitive items arrive intact, regardless of the shipping conditions they encounter. Furthermore, the focus on sustainability within the industry has led to the development of sustainable industrial packaging solutions. These eco-conscious options are engineered to minimize environmental impact without compromising on protection or brand visibility. Companies are increasingly adopting biodegradable and recyclable materials, aligning their packaging strategies with broader corporate social responsibility initiatives. This dual emphasis on protection and sustainability positions custom industrial packaging as a strategic asset for brands looking to stand out in the marketplace while also meeting their environmental obligations. As the demand for both robust packaging solutions and sustainable practices continues to grow, the industry is likely to see further innovation that balances performance with environmental stewardship.

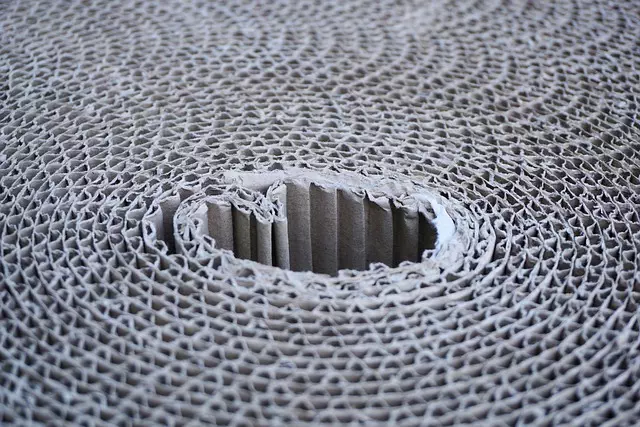

Key Considerations for Choosing Sustainable Industrial Packaging Materials

In the realm of industrial packaging, sustainability has become a paramount consideration in the selection of materials and solutions. Companies are increasingly looking for industrial packaging options that not only protect their products during transit but also minimize environmental impact. Sustainable industrial packaging materials are designed to reduce waste and energy consumption throughout the packaging lifecycle. These eco-conscious choices range from recycled paper and biodegradable plastics to innovative, compostable alternatives that can safely decompose after use. Opting for sustainable materials not only aligns with corporate social responsibility goals but also appeals to an environmentally aware consumer base. Custom industrial packaging solutions that prioritize sustainability can be tailored to fit specific product needs while adhering to stringent environmental standards, ensuring that the packaging serves its purpose without compromising the health of our planet.

Selecting the appropriate sustainable industrial packaging involves a careful analysis of various factors such as material composition, supplier practices, and end-of-life scenarios. It’s crucial to evaluate the entire supply chain for each potential material to ensure that it contributes positively to environmental objectives. For instance, selecting packaging made from recycled content reduces demand for virgin materials and energy-intensive production processes. Additionally, the design of custom industrial packaging can be optimized for reuse or easy disassembly at the end of its useful life, facilitating recycling or composting. By integrating these sustainable practices into the packaging process, businesses can significantly lower their carbon footprint while maintaining the integrity and functionality of their products during shipment.

Case Studies: Successful Implementation of Eco-Friendly Industrial Packaging

In the realm of industrial packaging, the shift towards sustainability has been a game-changer for businesses looking to minimize their environmental impact while ensuring product integrity during shipping. A notable case study involves a leading beverage company that transitioned to sustainable industrial packaging solutions. This company replaced its traditional plastic crates with biodegradable alternatives made from plant-based materials. The result was a significant reduction in carbon footprint without compromising on the protection of their products. Another example is a tech giant that implemented custom eco-friendly packaging for its sensitive electronic devices. By designing a packaging system that utilized recycled paperboard and soy-based inks, the company not only achieved a 30% reduction in greenhouse gas emissions but also demonstrated to consumers and stakeholders its commitment to sustainable practices. These case studies highlight the potential for industrial packaging solutions to be both environmentally friendly and effective in protecting goods during transportation. As companies continue to explore the benefits of sustainable industrial packaging, the industry is likely to see a surge in innovation, with new materials and designs that prioritize environmental stewardship without sacrificing performance or functionality. This shift not only aligns with global sustainability goals but also presents an opportunity for businesses to differentiate themselves in the marketplace, showcasing their dedication to corporate social responsibility and setting a new standard for the industry.

Innovative Technologies in Industrial Packaging Design

Innovative technologies are revolutionizing the field of industrial packaging design, offering solutions that cater to both the protection of goods and the promotion of sustainability. Advancements in materials science have led to the development of sustainable industrial packaging options that are both eco-friendly and robust. These new packages not only safeguard products from the rigors of transportation but also significantly reduce the environmental footprint typically associated with packaging waste. For instance, biodegradable and compostable materials are increasingly being used to create packaging solutions that decompose naturally after use, aligning with global sustainability goals.

Furthermore, custom industrial packaging has benefited from technological enhancements such as digital printing and 3D modeling, enabling manufacturers to tailor packaging designs to the exact specifications of their products. This level of customization ensures optimal product protection during shipping, reducing the likelihood of damage or spoilage. The integration of smart technologies like IoT sensors in packaging further adds a layer of security by monitoring the condition of goods in real-time, providing valuable data that can be used to improve supply chain efficiency and accountability. These advancements underscore the industry’s commitment to evolving with technologies that not only secure products but also contribute to a more sustainable future.

The Impact of Customization on Cost Efficiency and Product Safety in Shipping

In the realm of industrial packaging for shipping, customization plays a pivotal role in optimizing both cost efficiency and product safety. Companies that invest in bespoke solutions for their packaging needs can significantly reduce shipping costs by minimizing material usage and optimizing package dimensions for various carriers. This tailored approach ensures that each package is engineered to fit the specific product it contains, which not only saves space but also reduces the likelihood of damage during transit. The precision of custom industrial packaging solutions also allows for a more snug fit, protecting products from environmental factors and rough handling throughout the supply chain. Furthermore, these custom-fit designs can often be crafted from sustainable materials, aligning with corporate sustainability goals and reducing the environmental footprint associated with shipping. By adopting sustainable industrial packaging, businesses demonstrate a commitment to environmental stewardship while also benefiting from a more resilient and cost-effective shipping process. The integration of these eco-conscious materials and designs not only safeguards products but also positions companies as forward-thinking leaders in their respective industries.

The benefits of customization extend beyond initial savings, as it often leads to long-term cost reductions by streamlining operations and reducing waste. Custom industrial packaging solutions are tailored to the exact specifications of the product, which means less excess material and fewer resources used in the production process. This not only reduces the overall cost but also decreases the environmental impact of packaging waste. In terms of product safety, custom packaging is designed with the particular vulnerabilities of the product in mind, ensuring that it is adequately protected from the point of origin to the moment of delivery. The result is a more secure supply chain, where products arrive undamaged, and costly returns or replacements are minimized. The strategic use of custom packaging in industrial settings is thus a critical component for businesses looking to enhance both their financial performance and their commitment to responsible shipping practices.

Future Trends and Advancements in Sustainable Industrial Packaging Solutions

As industries continue to evolve, the demand for sustainable industrial packaging solutions has become paramount in addressing environmental concerns and meeting consumer expectations. Innovations in materials science are leading the charge towards more eco-friendly options, with a focus on reducing reliance on non-renewable resources and minimizing waste. Biodegradable and compostable materials, such as plant-based plastics and bio-composites derived from agricultural by-products, are gaining traction as viable alternatives to traditional petroleum-based packaging. These advancements not only reduce the carbon footprint but also align with the growing trend of circular economy principles, where packaging materials can be reused, recycled, or safely biodegraded after use.

Custom industrial packaging solutions are increasingly incorporating smart technology and design optimization to enhance their functionality and sustainability. Digitalization plays a crucial role in this transformation, enabling precise material usage and reducing waste. For instance, digital printing technologies allow for on-demand packaging with minimal excess, while 3D modeling and simulation software optimize package designs to better protect contents and use materials more efficiently. Additionally, the integration of IoT devices into packaging enables real-time monitoring and tracking throughout the supply chain, which not only ensures product integrity but also promotes responsible resource management. As these trends continue to shape the industry, companies are expected to adopt more sustainable practices, driving the market towards greener alternatives in industrial packaging solutions.